EAS Ejector Couplers

EAS Ejector Couplers

Connecting and disconnecting the mold ejector rods is a time-consuming and sometimes difficult task on injection molding machines, especially the larger ones. Our hydraulically and pneumatically operated ejector couplers solve this problem in a simple and fast way.

EAS change systems offers utility connection made easy, fast and fool proof, for the quickest connection possible. We are well known for our quick mold and die change systems, from fully automated magnetic clamping systems to single hydraulic clamping components. But media connectors are equally important when it comes to the smartening of your changeover procedure. Spillage or breakage will not help a speedy change of tools.

Tedious job

More often than not, every time you need a mold changed, you will have to disconnect the ejector pins – or knockout bars – from the machine’s ejector cylinder – and reconnect them at the end of each changeover procedure. A tricky task: the ejector pin needs to be held in place by a headed bolt passed through a small hole in the machine back plate which is then threaded into the ejector pin. Depending on the size of the mold, this operation must be carried out almost without visual guidance, in a very tight working space. With a really large mold, it may even be necessary to virtually climb onto the machine to gain access to the ejector pins. A laborious and dangerous task, to be performed with the utmost caution.

With the high-mix/low-volume production we often see today, this is a job that literally begs automating. Eliminating this hazardous and time-consuming job and at the same time preventing spillage with self-locking couplers however, is withing your grasp. The EAS program offers multi couplers, ejector couplers and knockout couplers, increasing safety as well as speed. The couplers can be used for the connection of water or air, hydraulic oil, steam and hot oil, or e-connectors. Installation is quick and simple, and they can easily be integrated on existing as well as new, original equipment.

Floating design

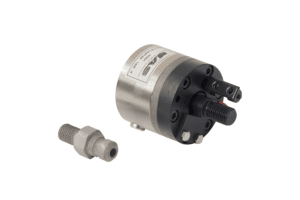

The ejector coupler allows for an automated solution, connecting the machine ejector plate to the tool ejector, when it is loaded. The coupler can be either hydraulic or air operated and has a floating design to accommodate for misalignment between the coupler and the male adapter.

Self-locking no spill couplers integrate into the EAS multi couplers. These clean-break, no-spill couplers are suitable for cooling water and air connections.

The electrical connections can accommodate sensor signals, power and heating lines. Depending on the couplers used in the multi coupler solutions, as well as the amperage and the voltage of the electric connections, there is a wide range of electrical connectors with different pin connections.

Configurations

Automatic ejector couplers are available in various sizes and capacities – and for large as well as small injection molding machines. There are available for different configurations.

EUROMAP configuration – Built to VDMA 24465, part 5 industry standards, these units are hydraulically operated and single acting. Each model is delivered with two proximity switches that indicate coupling mode. Capacities range from 20, 50, 100 to 200 kN.

SPI configuration – Available for 1” or 2” diameter size ejector patterns, these units simply push together when the mold is loaded. For the mold-release function, pressure is applied. Proximity switches to signal coupling mode are available for each model.

QMC all the way

These couplers are just one innovative QMC example to help minimize manufacturing costs in the plastic injection molding and related industries. EAS offers different solutions, not only optimizing changeover procedures but also for keeping a mold in excellent condition. Clamping systems, solutions for mold transportation like time-saving rollers, mold-change tables or manual and electric mold-cars help turning your injection molding process into a smart process. Your molds will last longer, your staff stays safe and your output increases. A combination of mold transportation with clamping systems boosts your production process thanks to a tremendous reduction in changeover times.

And should specialized applications require tailor-made solutions, our experienced engineers and technicians are available to develop and implement customized QMC solutions to suit every need – whatever the use, wherever the location.

No comments