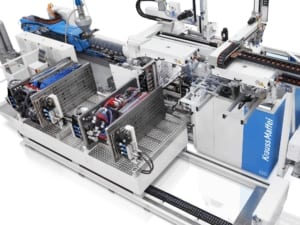

MCS 4K Machines

Magnetic clamping systems (MCS) are easy to use and reduce changeover time thus increasing productivity. These systems are just one of many ranges of solutions that help increase productivity and reduce costs and risks. Enhancing safety for personnel as well as molds and equipment.

Evolution and updates

Usage of magnetic clamping in the injection molding industry has grown drastically since the 1990’s. The greater flexibility as compared to hydraulic clamping is one of its greatest strengths. Over the decades more advanced systems have come on the market, leading to a higher degree of safety. The current generation of systems comes with flux and force measurement, redundancies in safety channels, and industry 4.0 readiness.

To transfer the advantages of the magnetic clamping system from standard injection molding machines to the special application of 4K injection molding machines, EAS offers a special magnetic platen for the rotating side created for 4K machines.

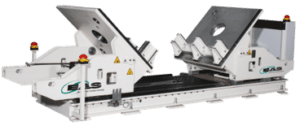

Rotary platens

Rotary platens require a special adaptation to a magnetic clamping system to deliver the same benefits as on traditional injection molding machines. EAS has developed a range of solutions which exceed industry guidelines in safety and usability.

Slip ring contacts in the rotational joint only allow for operation of the magnetic clamping system in fixed positions. This reduces the risk of electrical failures and subsequent damage to both the injection molding machine and the magnetic clamping system.

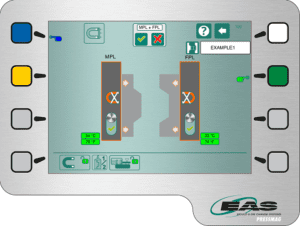

The system is available with Euromap 70.0 , 70.1 and with a full integration into the machine controls ( either through CANBUS, Modbus RS 485 or TCP/IP connections). This means the magnetic clamping is completely integrated into the safety circuit of the machine.

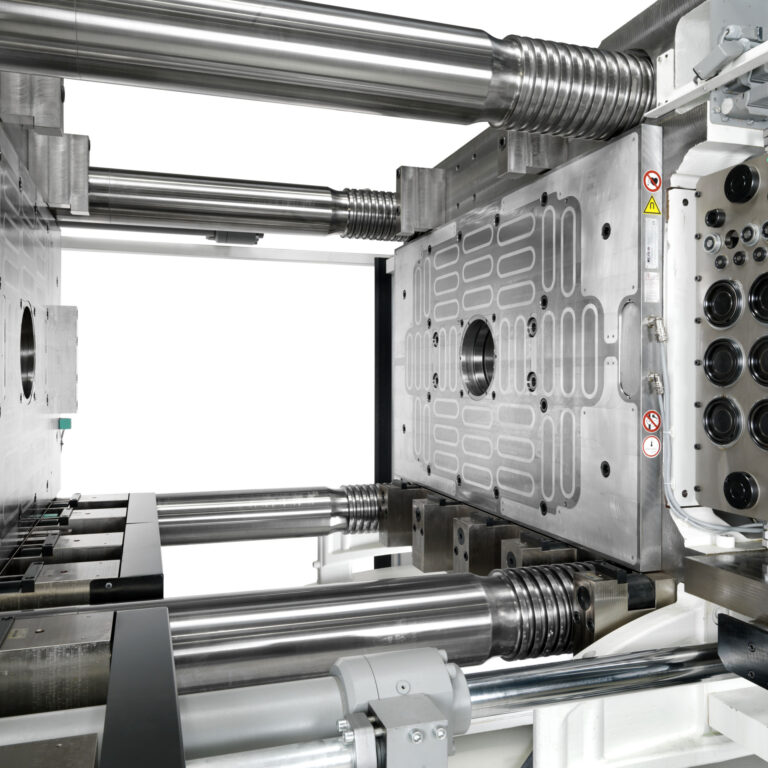

It is safe!

An additional feature, pioneered by EAS, adds pneumatic cylinders onto the magnetic system which mechanically lock into place when actuated. Integrated sensors monitor the position of the locked pins and put the machine into e-stop if any slippage of the mold is detected. This is in addition to the existing proximity sensors, temperature sensors, and flux and force measurement. On selected machine brands a full integration of the magnetic system controls into the machine controls is also available, allowing to the machine to adjust opening force based on the measured clamping force of the system. The EAS system compares clamping forces each time you clamp a mold again thus indicating if there are any issues with the mold or the system prior to operating the machine.

No comments