Reliable production with little or no people on site with EAS

More relevant than ever :

Reliable production with little or no people on site

We are experiencing challenging times, to say the least. For EAS change systems, these are the times in which their products and solutions prove themselves most of all. One-man control for changeovers of even the largest molds is reality. Their business results speak for themselves.

Automating changeover processes is more vital than ever. Preferably with as little staff as possible. And how about troubleshooting? Imagine software that allows for 80 to 85 % of alarms to be dealt with remotely. Vincent Nijzink, CEO of EAS change systems: “With our EAS Remote Access Device we can access the controls of our mold change equipment from any location. Most of the faults stalling a system can be easily spotted by analyzing the data collected by sensors. We have a complete and extensive log of machine handling and statuses. This not only offers detailed information on where and when exactly an alarm was triggered, but also the corrective measure needed. This measure can either be executed remotely or a maintenance engineer can be directed with specific instructions. Saving the time of having to analyze on-site.”

Besides the Remote Access Device, EAS customers – in Mexico, as in all off North America – can rely on an extensive service network with expert – and Spanish-speaking – technicians.

Automated systems

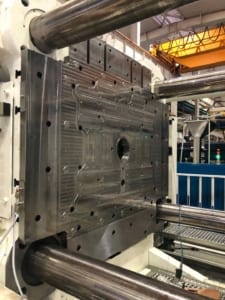

Changing a production process from one product to another is the focal point of every solution EAS has ever developed. Quick clamping and coupling, mold tables and carts, these are just a few of the components that constitute a solution reducing not only time but risks as well.

Changeover times can be reduced to minutes and personal safety is increased to the max.

Clamping systems offer quick and safe mold changes. Be it hydraulic or magnetic, each system offers maximum security combined with user friendly controls. Different self-locking no-spill couplers can be combined to form a multi coupler solution suitable for different media. Mold tables or carts can service molds up to the largest used in the industry. Fully automated with AGV’s or manually driven: Just what the situation requires. Turning an injection molding process into a smart process, molds will last longer, staff stays safe and output increases.

Q1 and Q2 2020

“In recent years we set out to expand our North American sales organization as well as our distributor network.” Vincent Nijzink rooted himself in the new head office in South Carolina to be closer to the action. “Three years ago, we started with our North American sales strategy. We moved our head office to its present location and expanded our sales force. We set about to spread the word regarding quick change systems and the result is accordingly. The first two quarters of this year, even with the present pandemic causing a whole new and unprecedented scenario, we managed to increase sales number with 150 % as opposed to 2019. Had we not had a pandemic, we would have surpassed 200 % increase. But there you are. And the need and benefits to further automate systems – given the challenges in many factories – has taken ground. So, I am optimistic about our prospects. Our whole sales staff however, would just like to go out and shake a hand on a deal instead of a virtual handshake.”

No comments