Connectivity Solutions

, ,

Worldwide, there has been a shift toward products that are more dedicated and personalized. This trend is given by the need to further optimize the processes of production and molding.

Aiming to increase the quality of the printed product and lower production costs and energy savings, quick die change, especially the SMED (single-minute exchange of dies), is the way for the sheet metal industry as a whole. One of the easiest steps to take toward this is automation for connectivity of fluids during die-change operation.

SMED Solutions

We help you produce with higher speed and increased flexibility. With solutions that are designed and built for easy installation on existing and new original equipment, EAS change systems have a proven track record as a turnkey project supplier. We have a worldwide reputation for innovative excellence in quick mold change (QMC) and quick die-change (QDC) technology. Thanks to EAS, clamping and release of molds and dies is done in minutes instead of hours. Our high-quality mono and multicouplers serve a number of branches.

Coupler Solutions

EAS offers easy, manually-operated couplers for water or air, hydraulic oil, steam and hot oil, or e-connectors. Monocouplers are used for quick coupling, with one-hand operation without any debris. Self-locking nonspill couplers integrate into the EAS manual multicouplers. These clean break, no spill couplers are suitable for cooling water and air connections. Self-locking couplers contain separating forces that occur when pressurized. By containing these separating forces within the body of the coupler, stress on the coupler plates as well as on the push/pull cylinders is reduced. This makes the EAS multicouplers simple and less expensive than other solutions using locking mechanisms to keep the two multicoupler plates together.

EAS Multicouplers

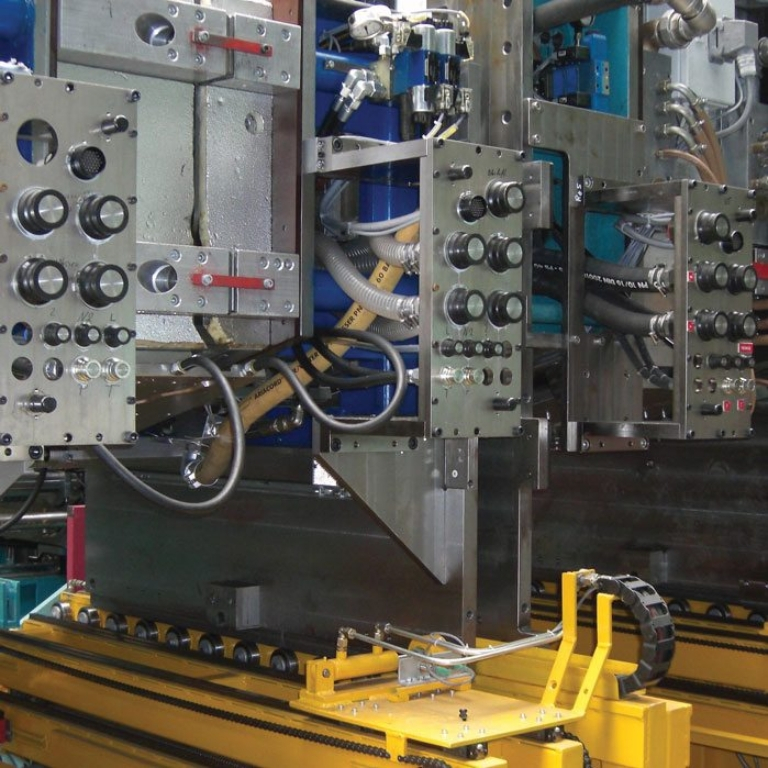

Strong of its know-how and experience gained, EAS has a large and varied set of solutions for the sheet metal sector, among which are groups of customized automatic multicouplers.

Attuned to the customer specification, couplers of different types and numbers are placed on a single plate. This way, the quick release is ensured while connecting all utilities in a short timeframe without errors that come with standard connections, a common risk when manually connecting several lines.

Only one operator is necessary for all three phases of the mold and/or die change including handling, clamping and utility connection duties. This automation carries its benefits in terms of personnel, safety, operational planning and continuance.

For both horizontal and vertical loading of machines, the machine side multicoupler is mounted on a fixed location and mounted multicoupler plates are used for the mold and/or die. This way, each coupler is firmly connected to the counterpart, avoiding the bending of multicoupler plates and leakage of the individual coupler connections.

Many multicoupler systems are used not only to connect water, air or hydraulic lines, but also in combination with electrical connections such as sensor signals, power and heating lines. Depending on the couplers used in the multicoupler solutions, as well as the amperage and the voltage of the electric connections, EAS change systems offers a wide range of electrical connectors with different amounts of pin connections.