Denso

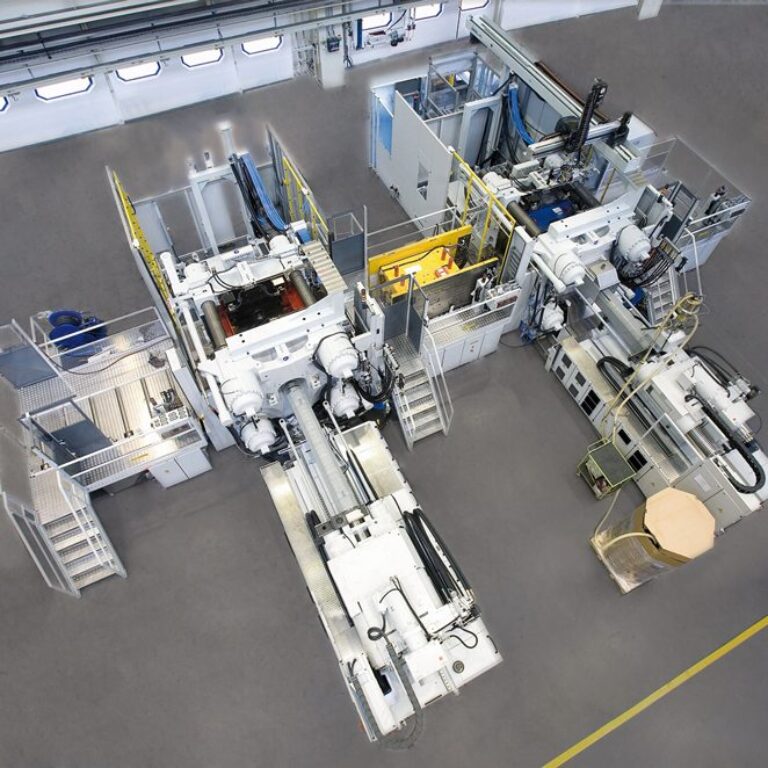

An example of our QMC automation solutions is the solution engineered and installed for Denso, a well-known global manufacturer of automotive climate control products. EAS equipped a range of 1300-ton injection molding machines in different locations around the world. An international quicker mold change process:

Service and installation around the world

On each of the multiple international locations of the manufacturer, EAS has installed all components needed to accelerate the mold change process.

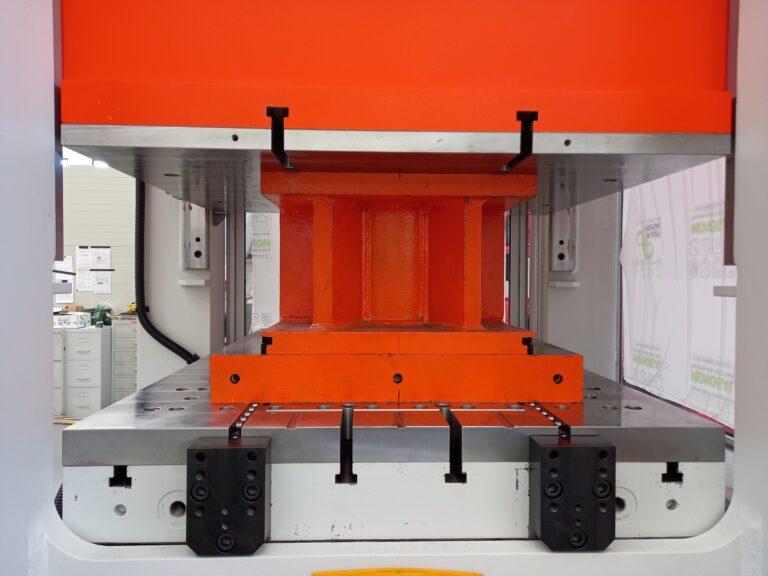

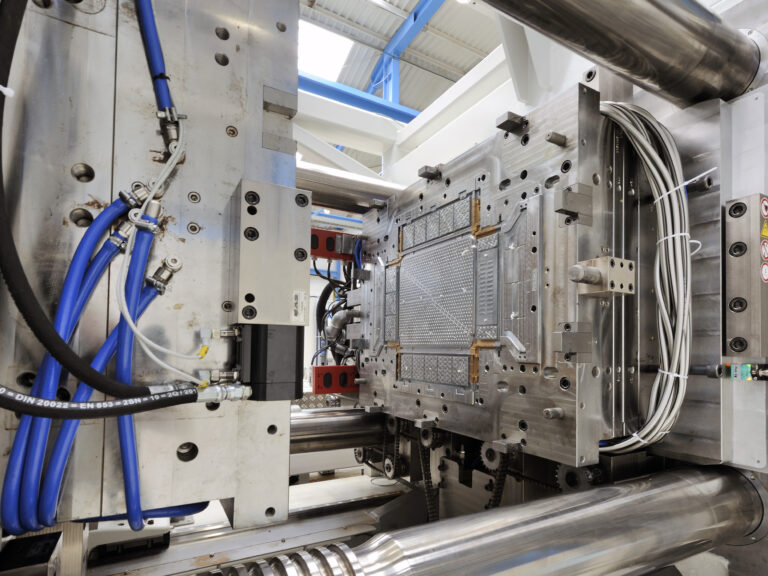

Different clamping and coupler solutions on the injection molding machines. Mold change tables to assist transfer, preheating and cooling down besides the machines. And on the molds, the components needed to monitor and help the locking part of the change. Thanks to the operator walking platforms and the control interfaces, all can be safely monitored and controlled.

A fully automated mold change in less than 50 seconds

The result is a full automatic mold change in less than 50 seconds, reduced stock, more than 95% machine availability and a safe and clean working environment with less labor costs.

Here’s another example of how a quick mold change process works in practice:

Deze video wordt niet getoond omdat er (nog) niet akkoord is gegaan met het plaatsen van cookies.

Wijzig keuze

SERVICE AND INSTALLATION AROUND THE WORLD

The following products have been installed on the multiple international locations of the manufacturer:

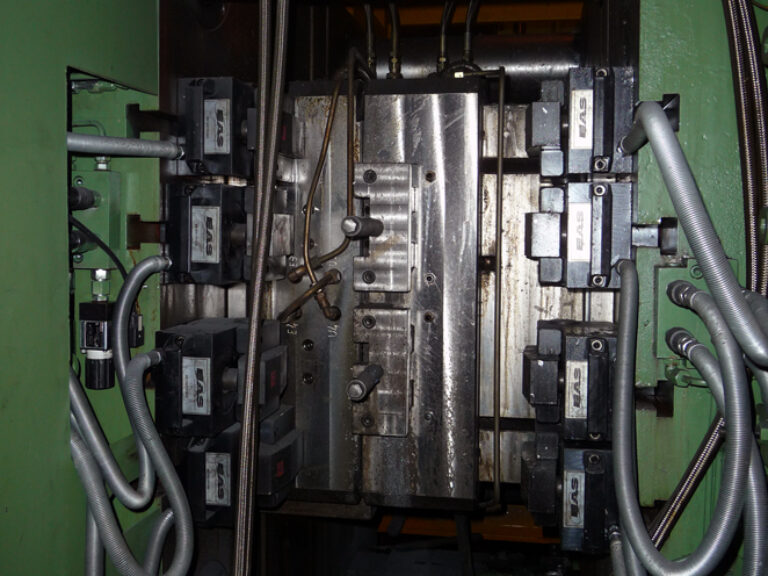

On the injection molding machines

- hydraulic clamping cylinders

- Driven rollers

- Ejector couplers

- Mold centering cylinders

- Multi couplers

Besides the machines

- single mold change tables : for molds with a maximum weight of 15 ton.

All mold change tables feature

- powered rollers

- multi couplers

- Pre heating stations

- Cooling down options

- Operator walking platforms with safety gates

- Control interfaces with machine controls

On the molds

- multi couplers

- ejector rods

- mold half locking devices