Inspection made EASY

Opening and closing a mold in seconds

Inspecting and maintaining a mold can be an arduous task. The mold needs to be handled gently in order to avoid damage. The quality of the production depends largely on the quality of the mold, making it often the most important tool in your production process.

That is why an inspection unit is an excellent investment. It helps to simplify the maintenance of your molds, and makes repair, cleaning and preparation for use easier than ever. This will not only reduce your production costs but also enable you to react flexibly to new orders without losing valuable production time for time-consuming tooling up or changing molds.

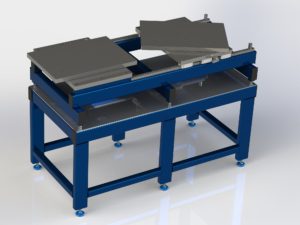

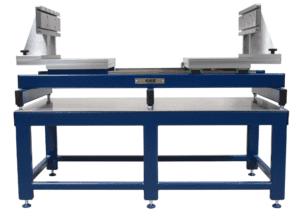

EIT units

With a well-maintained mold, which is kept in the best possible condition, you will not only get the best quality and longevity of the mold itself, but you will also achieve the shortest downtimes and safest turnovers. EAS offers a wide range of mold care solutions, in which the EIT inspection units play a major role, for molds ranging anywhere from 1,500 up to 6,000 kilograms.

EIT inspection units are very easy to operate. They offer one fixed and one movable platen and allow for a 360° rotation of the movable platen. Positions can be locked to increase safety and brackets are available in three different versions: magnetic, mechanic and forged. Depending on the maximum weight of the mold and for each specific set up, EAS will help find the best solution.

Easy access

Molds can be opened and closed in only a few seconds and all parts of the molds can be reached. So the advantages are not only found in the costs saved in reducing changeover time and improving longevity, they also include the reduction of the labor costs associated with tooling up. The inspection unit allows one operator to perform inspection, cleaning and repair, without any further assistance. There are several options possible to further increase safety and to integrate testing functions which can even be integrated into the controls.

Complete program

The EAS mold care program covers mold handling from storage to transport on site to loading and unloading of the machine. Automated and carefully guarded, the solutions range from mold change tables, inspection and maintenance units to pre-heating and mold rotating equipment. All to reduce manual operations, thus offering safer working conditions benefitting personnel as well as the tools. The flexibility gained in your changeover, will allow you to reduce inventories due to flexible production and thus secure the future of your company and your employees.

EAS offers different solutions, not only for keeping a mold in excellent condition but also for optimizing changeover procedures in general. Clamping systems, coupler systems such as manual and automatic multi couplers, ejector couplers as well as solutions for mold transportation like time-saving rollers, mold-change tables or manual and electric mold-carts help turning your injection molding process into a smart process. Your molds will last longer, your staff stays safe and your output increases. A combination of mold transportation with clamping systems boosts your production process thanks to a tremendous reduction in changeover times.

All of EAS’ solutions are focused on your tool lasting longer, producing the highest quality possible. An unrivaled way to get the best value for your money.

No comments