Quick Mold Change Systems

HOW TO IMPROVE YOUR PLASTIC INJECTION MOLDING PRODUCTIVITY

Wouldn’t it be great if we could improve the productivity of our facilities? Increasing factory productivity is crucial for staying ahead of your competition in plastic injection molding.

Optimizing run size, reducing scrap, and reducing setup times and preventive maintenance are typical injection molding goals.

Your mold handling team knows exactly what to do as long as your molding activities are excellent and the run size is set correctly. While mold-loading and unloading personnel are properly trained, it is still a time-consuming process.

It usually pays off very quickly to speed up mold changeovers. Quick mold change systems provide significant benefits: not only will QMC reduce your production time, but it will also make plastic injection molding a safer process.

Contact our sales and project management teams to learn how we can help your company succeed.

THE BENEFITS OF QUICK MOLD CHANGE SYSTEM

With our QMC solutions, you save valuable time and money:

- Reduce inventory costs by up to 60%

- Reduce labor costs by up to 40%

- Reduce machine downtime by up to 15%

- Reduce manufacturing costs by up to 20%

- Optimize operator safety

- Improve the working environment

- Gain a competitive edge

These direct and indirect advantages have a huge impact. The mold changeover time can be immensely reduced – from hours to minutes.

See in this video how a mold change is done in only two minutes.

QUICK MOULD CHANGE SYSTEMS

The more you can automate your injection molding facility productivity, the higher the benefits. EAS offers a complete set of quick mold change systems to help you fasten your complete mold change process step by step. From cost-effective products to total solutions, all Quick Mold Change (QMC) systems give you direct as well as indirect benefits.

You can automate your systems by different levels thanks to our 6 solutions :

- EAS Clamping Solutions

- EAS Mold Handling Solutions

- EAS Couplers Solutions

- EAS Maintenance Solutions

- EAS Ejector Coupler Solutions

- EAS Turnkey Solutions

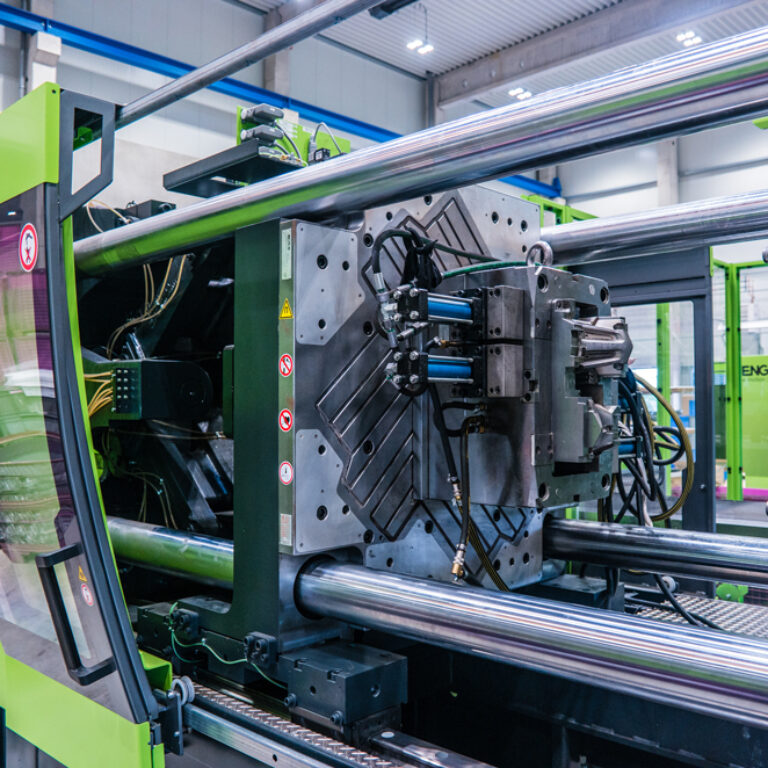

MOLD CLAMPING SOLUTIONS

In most cases, clamping will be the first step in reducing mold change time. Quick clamping equipment not only makes operations faster but installing this equipment also increases safety. The mold handling no longer requires manual operations. EAS Clamping Solutions propose a large variety of clamp to fit a large variety of application and mold. You can find our Magnetic Pressmag LP and SP to fix your mold into the machine by using magnetic technology. Besides this, you can find our hydraulic clamps (MOD, ELY, and HECS) as another option.

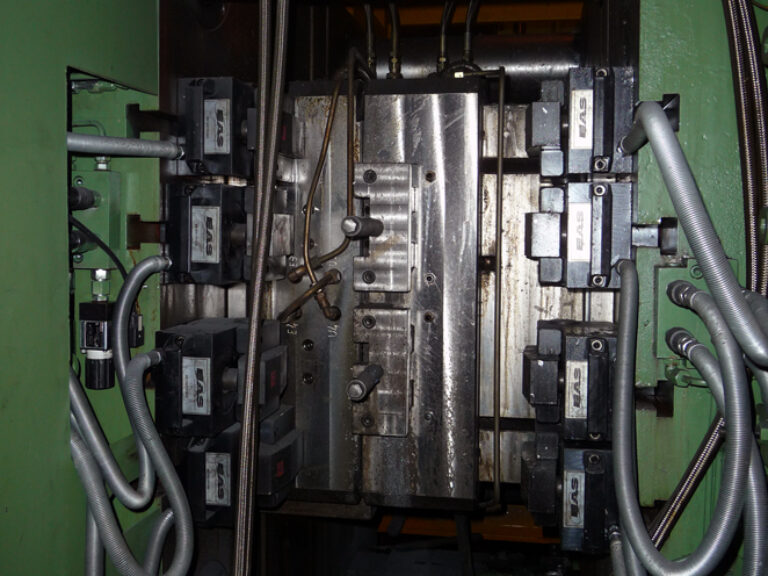

COUPLER SOLUTIONS

Coupler solutions tend to be the next step in reducing mold change time. In order to fit all applications again, three types of coupler solutions are available: Mono couplers, manual multi couplers, and Automatic multi couplers. Mono couplers are the most used form of couplers widely and allow a quick and simple connection of circuits one by one. EAS manual multi-couplers save time and ensure safe operation. Water, electrical, and/or hydraulic connections are all possible with manual multi-coupler systems. Our well-known automatic coupler solutions’ couplers have proven to be excellent mono couplers as well. They are available in a variety of sizes and can handle a wide range of flows. When connected and disconnected, the clean break feature on these couplers prevents any water spillage.

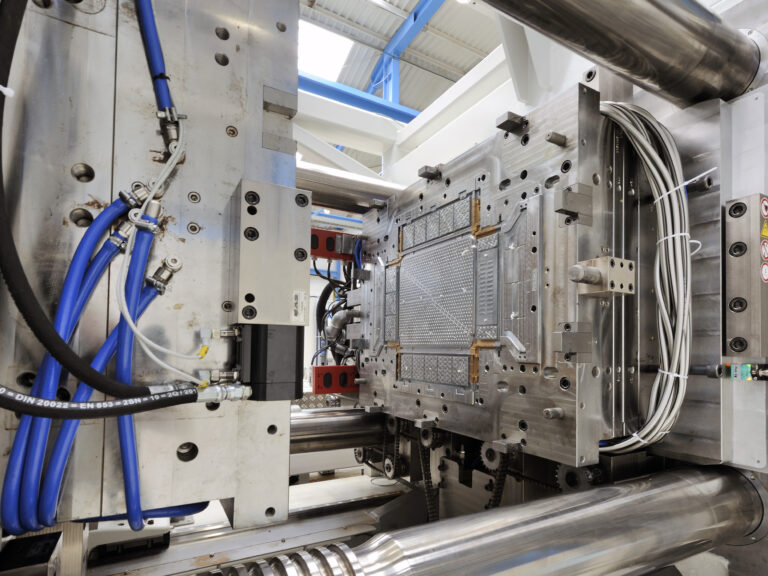

MOLD HANDLING SOLUTIONS

Mold handling solutions plays also an important role in reducing mold change time. Handling equipment makes mold exchange and transportation easier, safer and faster. EAS handling solutions are divided into three categories: Mold Change Tables, Mold Change Cars and the Transporter. EAS Mold Change Cars are a good solution to move your mold easily from one place to another. Depending on the weight of the mold, the mold can be transferred manually or powered into the machine. EAS Mold Change Tables are another solutions that can help load and unload your mold more easily. Single station mold change tables on each side of the injection molding machine, along with driven rollers on the table and in the machine, allow for extremely fast and automated mold changes. Using a transporter, dies are brought from the storage or maintenance area to the press and returned.

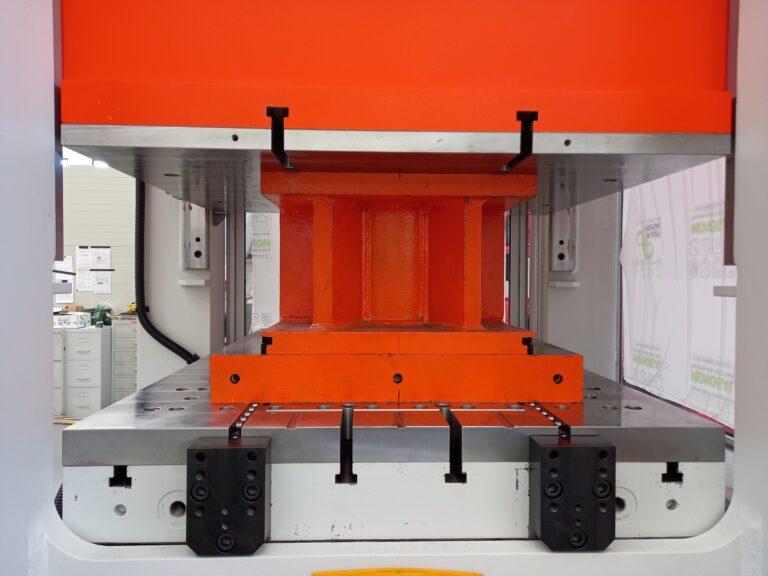

MOLD MAINTENANCE SOLUTIONS

EAS also proposes you the possibility to automate your mold maintenance for a safer, and faster process. There are 3 different solutions for this: Inspection Unit, Mold rotator, and Inspection tables. The mold rotator from EAS is a safe and effective way to rotate tools the EAS Electric Mold Rotator provides 90°. Mold rotators from EAS are capable of handling loads up to 60 tons. Molds and dies can be turned to lift one half of a mold or to move the mold. No hydraulics are necessary as the entire unit is electric. With EAS Inspection Unit, maintain your expensive tools safely and easily. Molds and dies should be inspected and serviced more efficiently, rather than using slow and sometimes dangerous jacks, levers, and cranes. Tools can be opened and turned safely with inspection units. The EIT table allows a mold to be opened and closed quickly for maintenance, repair, cleaning, preparation for injection, or assembly during manufacturing.

EJECTOR COUPLER SOLUTIONS

Some molders require the connection of the ejector system on the machine to the ejector system on the mold in addition to mold clamps, multi-couplers, and change systems. A simple automatic coupler system can replace the time-consuming manual connections of the ejectors. The floating design of the EAS ejector couplers allows for greater misalignment between the ejector coupler and the male adapter, which is mounted to the mold ejector rod.

TURNKEY SOLUTIONS

EAS Change Systems is one of the few global QMC and QDC suppliers that can provide you with complete turnkey solutions.

We have been the one-stop, all-in-one provider for mold or die change automation on a number of projects. This solution includes all previous separate solutions in one, for an automation fully EAS.